Air conditioning systems are essential for maintaining comfort during both hot and cold conditions. To ensure your AC unit operates efficiently, it is critical to keep the refrigerant gas at the correct level. Over time, AC units can lose refrigerant due to leaks or other issues, leading to a drop in cooling efficiency. Consequently, refilling the AC gas is imperative for restoring its performance.

This comprehensive guide will delve into the AC gas filling process, outline the necessary safety precautions, detail the equipment needed, and discuss the various types of AC gases. We will compare the performance of R22 and R410A refrigerants and examine common causes of AC gas leaks. Additionally, we’ll provide a step-by-step explanation of how is AC gas filling done to complete your understanding of maintaining your air conditioning system.

Table of Contents

Safety Measures

Before delving into the procedure for AC gas filling, it’s crucial to understand and adhere to important safety measures. Working with refrigerant gases can be hazardous, and proper precautions should always be taken to protect yourself and others.

Use Gloves

When handling refrigerant gases, wearing gloves is essential. These gases can harm the skin and cause frostbite if they come into contact with it. Use nitrile gloves or gloves designed for refrigerant handling to protect your hands.

Wear Protective Eyeglasses

Refrigerant gases can release high-pressure gas when they escape, which may cause eye injury. Wearing protective eyeglasses or safety goggles is important to prevent any potential eye damage.

Our Recommendations

While safety measures are vital, ensuring you have the right safety equipment can make the process of AC gas filling much safer and more efficient. Here are our recommendations:

Gloves

Invest in a good pair of nitrile or rubber gloves for refrigerant handling. These gloves offer protection against exposure to refrigerant gas and other chemicals you might encounter during the process. Our picks for gloves:

3M Cgl-Gu Nitrile Rubber Comfort Grip Gloves

DEX FIT Nitrile Work Gloves FN330, 3D Comfort Stretch Fit, Power Grip

Eyeglasses

Use safety glasses or goggles to protect your eyes from gas leaks or splashes during the AC gas-filling procedure. Standard eyeglasses may not provide adequate protection. Our top picks for eyeglasses:

3M 1611 Safety Goggles Hard Coat Eyewear, Over The Spectalar Eye Protector

Venus E-306 CHC ISI Certified Performance Eyewear Pack of 1, Lens Designed Hard Coated for High Impact Resistant

Equipment Required

To successfully fill AC gas, you’ll need the following equipment:

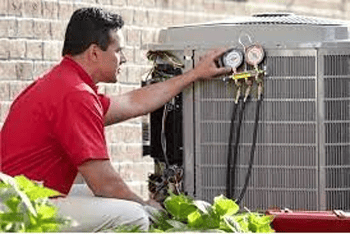

Manifold Gauge Set: This set includes gauges, hoses, and valves to measure the pressure and temperature of the refrigerant in the AC system. It helps you determine if your system needs a gas refill.

Refrigerant Canister: Refrigerant gases are available in pressurised canisters. You’ll need the specific type of refrigerant required for your AC system. Common refrigerants include R22, R410A, and others.

Refrigerant Recovery Machine (optional): If you’re working on a system that requires the old refrigerant to be removed and replaced, a recovery machine is necessary to extract and store the old refrigerant safely.

Charging Hose: This hose connects the refrigerant canister to the manifold gauge set and allows the controlled refrigerant to be transferred into the AC system.

Vacuum Pump (optional): A vacuum pump removes any moisture and non-condensable gases from the AC system before charging it with refrigerant.

Procedure for AC Gas Filling

Now, let’s walk through the process of AC gas filling step by step:

Safety Precautions

Before you start, ensure you have taken all necessary safety precautions by wearing gloves and protective eyeglasses.

Identify the Refrigerant Type

Determine the type of refrigerant your AC system uses. This information can usually be found on a label on the unit or in the user manual. The two most common types are R22 and R410A, but there are others.

Assess the Refrigerant Level

Using a manifold gauge set, attach the high and low-pressure hoses to the service valves on the AC system. Turn on the AC system and let it run for a few minutes to stabilise. Then, check the pressure readings on the gauges. The pressure readings should fall within the manufacturer’s specified range for a properly charged system. If the readings are too low, it indicates a low refrigerant level and the need for AC gas filling.

Prepare the Refrigerant Canister

Attach the charging hose to the refrigerant canister. Ensure that the hose is securely connected to prevent any leaks.

Connect the Charging Hose

Attach the other end of the charging hose to the low-pressure side of the manifold gauge set. This is typically the larger of the two valves on the service ports.

Charge the AC System

Slowly open the valve on the refrigerant canister, allowing refrigerant to flow into the system. Monitor the gauges as you do this to ensure that the pressure readings are within the recommended range. Avoid overcharging the system, leading to poor performance and potential damage.

Monitor and Adjust

As you add refrigerant, keep a close eye on the gauges and the air temperature from the AC vents. You may need to add or stop adding refrigerant based on these indicators. Aim to achieve the recommended pressure and temperature for your specific AC system.

Close the Valve and Disconnect

Once the AC system is properly charged, close the valve on the refrigerant canister and disconnect the charging hose from the low-pressure side of the manifold gauge set.

Recheck the Pressure

After completing the AC gas filling, recheck the pressure readings on the manifold gauge set to ensure they remain within the specified range.

Replace Valve Caps and Seal Any Leaks

Make sure to replace the valve caps on the service ports to prevent any leaks. If you encounter any visible leaks during the process, seal them with the appropriate sealant or repair the leak before completing the procedure.

Test the AC System

Allow the AC system to run for some time to ensure it is cooling properly. You should feel a significant improvement in the air temperature and overall performance.

Types of AC Gases

Two of the most common types of refrigerants used in AC systems are R22 and R410A. Understanding the differences between them is important when considering AC gas filling:

R22 (Freon)

R22, also known as Freon, was a widely used refrigerant in older AC systems. However, it has been phased out due to its harmful impact on the ozone layer. As a result, R22 is no longer manufactured, and its availability is limited. If your AC system uses R22, you may need to consider an upgrade to a more environmentally friendly refrigerant or have a certified technician handle any servicing or AC gas filling.

R410A

R410A is a more environmentally friendly and efficient alternative to R22. It is commonly used in modern AC systems and is known for its superior cooling performance. R410A is considered more sustainable and has replaced R22 in most new AC units.

Performance Difference Between R22 and R410A

The choice between R22 and R410A refrigerants significantly affects the performance of an AC system. Here are some key differences:

Efficiency

R410A is more energy-efficient than R22. It can provide better cooling while using less electricity, lowering energy bills.

Environmental Impact

R410A is known as a “greener” refrigerant because it doesn’t deplete the ozone layer, unlike R22. As a result, R22 is being phased out globally due to its harmful effects on the environment.

Compatibility

If your AC system was designed for R22, it may not be compatible with R410A. Transitioning to R410A would require significant modifications or replacing the entire system.

Cost

R22 is becoming more expensive and harder to find due to its phased-out status. R410A is more readily available and cost-effective.

Cooling Performance

R410A provides better cooling performance, making it a preferred choice for those seeking efficient and effective air conditioning.

Reasons for AC Gas Leakage

AC gas leakage is a common issue leading to decreased cooling efficiency and the need for AC gas filling. Several factors can cause refrigerant leaks:

Poor Installation

Improper installation of the AC system can result in leaks. This can happen if the refrigerant lines are not adequately sealed or the connections are loose.

Wear and Tear

Over time, the components of an AC system can deteriorate, leading to leaks. This can include corrosion of copper pipes, deterioration of rubber seals, or physical damage to the refrigerant lines.

Vibrations and Movement

Excessive vibrations or movement of the AC unit, such as from an earthquake or accidental bumping, can cause refrigerant leaks.

Manufacturing Defects

In some cases, manufacturing defects in the AC system can lead to refrigerant leaks. This is less common but still possible.

Lack of Maintenance

Neglecting regular maintenance can allow small leaks to go unnoticed until they become more significant and impact cooling performance.

Ageing Components

As an AC system ages, the likelihood of refrigerant leaks increases. Routine inspections can help identify and address any issues before they become major problems.

Accidental Damage

Accidental damage, such as puncturing the refrigerant lines during home renovations or landscaping, can result in refrigerant leaks.

Also Read

- Understanding the ”Cool” Factor: Different Types of AC Refrigerants

- Cooling Your Space: Selecting the Right AC Capacity Based on Room Size

- How to Choose Between 1 Ton and 1.5 Ton AC?

Conclusion

AC gas filling is an essential maintenance task to ensure your air conditioning system operates efficiently and provides a comfortable indoor environment. Following safety measures, understanding the type of refrigerant in your system, using the right equipment, and adhering to the recommended procedure are key to a successful AC gas-filling process.

While R22 and R410A are two common refrigerants, it’s important to choose the right one for your system to maximise performance and minimise environmental impact. Regular maintenance and addressing the causes of refrigerant leaks can help prolong the life of your AC system and ensure it continues to function optimally.

Frequently Asked Questions

Why is it important to maintain the proper refrigerant level in my AC system?

Maintaining the proper refrigerant level in your AC system is crucial for optimal performance. Refrigerants are responsible for absorbing and releasing heat to cool the air. When the refrigerant level is low, your AC system won’t cool efficiently, resulting in reduced cooling capacity and potentially higher energy consumption. Over time, low refrigerant levels can also damage the compressor and other components, causing costly repairs.

Can I perform AC gas filling independently, or should I hire a professional technician?

While homeowners can perform basic maintenance tasks, AC gas filling is best left to trained professionals. Handling refrigerants can be hazardous, and an improper refill can lead to safety risks, further damage to your system, and ineffective cooling. Additionally, refrigerant handling regulations vary by location, and unlicensed individuals may be subject to legal consequences. It’s recommended to hire a certified HVAC technician to ensure the job is done safely and correctly.

Are there any eco-friendly alternatives to traditional refrigerants like R22 and R410A?

Yes, there are environmentally friendly refrigerants available, often referred to as “green” refrigerants. One example is R32, which has a lower global warming potential (GWP) than R22 and R410A. Some AC systems are designed to use these alternative refrigerants. Still, it’s important to consult with a professional to determine if your system can be retrofitted or if a more eco-friendly system is a better option. Using green refrigerants can help reduce your carbon footprint.

How can I tell if my AC system is low on refrigerant, and is it always the cause of cooling problems?

Detecting low refrigerant levels in your AC system can be challenging for the average homeowner. However, there are some common signs to watch for, such as reduced cooling performance, warmer air blowing from the vents, and longer cooling cycles. If you notice these symptoms, your AC system may be low on refrigerant.